Solutions

“Revolutionary Solutions: Guruharkrishan Machinery’s Innovation for Plastics Industry Success”.

Medical Technology

Packaging

Technical Injection Moulding

Automotive & Mobility

We help you make the best of your business

Guruharkrishan Machinery specializes in manufacturing high-performance injection molding machines, catering to a diverse range of industries. Our cutting-edge solutions are meticulously designed to meet the unique demands of Automotive & Mobility, Medical Technology, Technical Injection Moulding, Packaging, and Electronics sectors. With a focus on precision engineering, our injection molding machines ensure the production of top-quality components critical to these industries. Whether it’s the intricacies of medical device manufacturing, the technical precision required in automotive parts, or the stringent standards of packaging and electronics, our machinery delivers reliable and efficient solutions. At Guruharkrishan Machinery, we take pride in being at the forefront of technological advancements, providing tailored solutions that contribute to the success and innovation of our clients across these diverse sectors.

We Manufactures These Machines :-

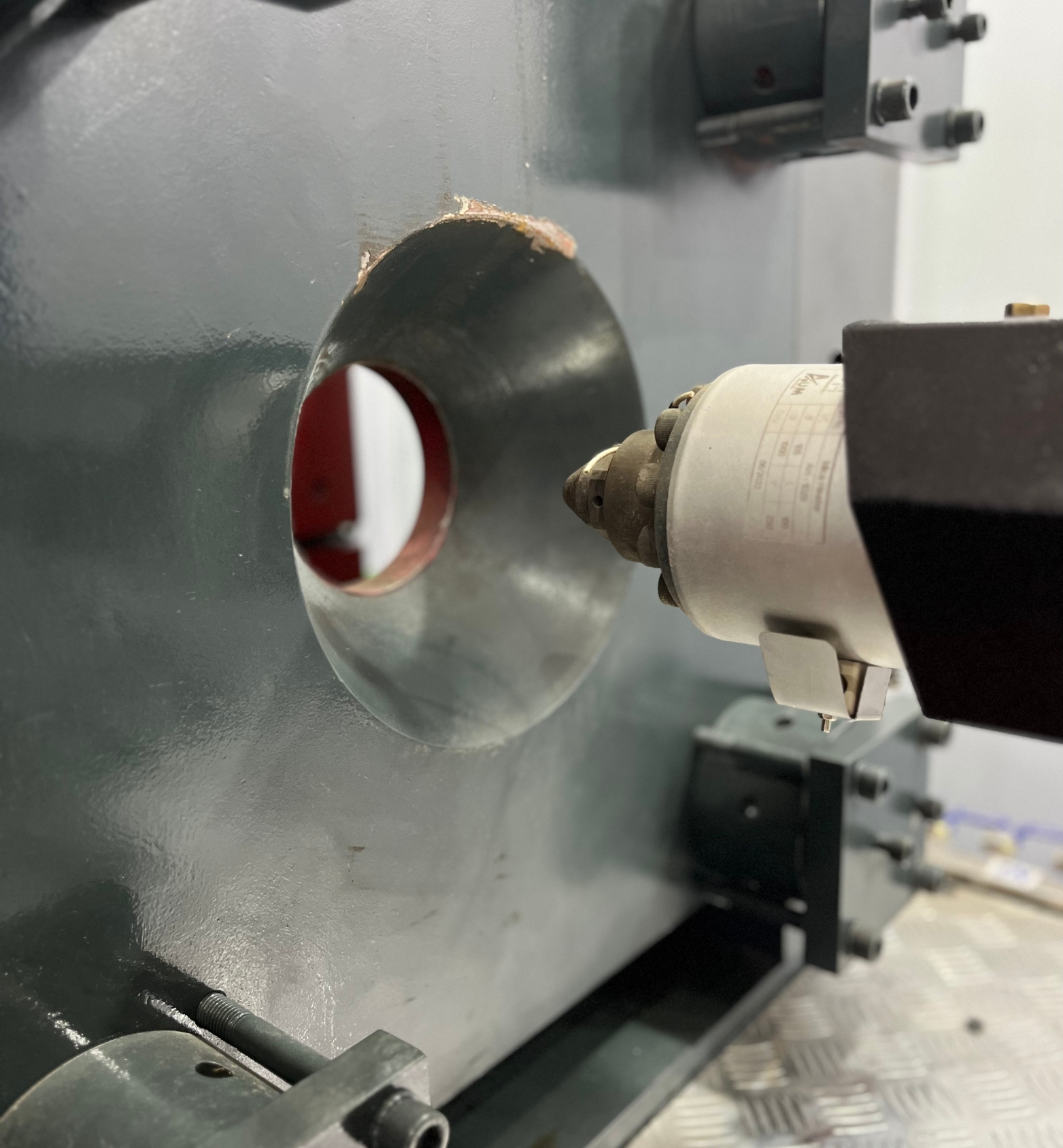

HORIZONTAL INJECTION MOULDING GHH-130S

The Guruharkrishan Machinery GHH-130S Horizontal Injection Moulding Machine represents a commitment to innovation, reliability, and precision in the field of plastics manufacturing. .

Integrated Control Concept

Integrated Control Concept

The Inovance Integrated Control Concept enhances the precision, performance, and overall functionality of our injection molding machines. With Inovance’s cutting-edge technology seamlessly fused into our machines, we offer our clients a superior manufacturing experience, setting new standards in quality and reliability. At Guruharkrishan Machinery, modern manufacturing.

1 of 4 Fast Clamping Unit

Fast Clamping Unit

The closing side of the e-cap is designed for cycle times of < 2 seconds under continuous load. An electric drive provides the necessary dynamics. An encapsulated 5-point toggle converts these into high-precision injection moulding machine movements.

2 of 4 Reduce Energy Costs

Reduce Energy Costs

Water-cooled, all-electric drives and flywheel storage reduce energy costs by up to 50% compared to hybrid machines.

3 of 4 Dynamic Injection Unit

Dynamic Injection Unit

The injection unit is tailored to the processing of HDPE. Together with the special screws developed for this purpose, it ensures reliable processing of the melt.

4 of 4

Integrated Control Concept

Integrated Control Concept

The Inovance Integrated Control Concept enhances the precision, performance, and overall functionality of our injection molding machines. With Inovance’s cutting-edge technology seamlessly fused into our machines, we offer our clients a superior manufacturing experience, setting new standards in quality and reliability. At Guruharkrishan Machinery, modern manufacturing.

1 of 4 Fast Clamping Unit

Fast Clamping Unit

The closing side of the e-cap is designed for cycle times of < 2 seconds under continuous load. An electric drive provides the necessary dynamics. An encapsulated 5-point toggle converts these into high-precision injection moulding machine movements.

2 of 4 Reduce Energy Costs

Reduce Energy Costs

Water-cooled, all-electric drives and flywheel storage reduce energy costs by up to 50% compared to hybrid machines.

3 of 4 Dynamic Injection Unit

Dynamic Injection Unit

The injection unit is tailored to the processing of HDPE. Together with the special screws developed for this purpose, it ensures reliable processing of the melt.

4 of 4HORIZONTAL INJECTION MOULDING GHH 450S

The Guruharkrishan Machinery Horizontal Injection Moulding Machine, model GHH 450S, is a high-performance solution designed to meet the demanding requirements of modern manufacturing. With a robust horizontal configuration, this machine offers precision and efficiency in the injection molding process. The GHH 450S is engineered for versatility, making it suitable for a wide range of applications across various industries.

VERTICAL INJECTION MOULDING GHV-70S

The GHV-70S is engineered to meet the demands of diverse industries, including Automotive & Mobility, Medical Technology, Technical Injection Moulding, Packaging, and Electronics. With a robust vertical design, this machine optimizes floor space utilization and offers exceptional control over the injection molding process. Its advanced features include a user-friendly interface, high-speed and high-pressure injection capabilities, and a versatile mold-clamping system, ensuring seamless production of intricate components with accuracy and repeatability.

Integrated Control Concept

Integrated Control Concept

The Inovance Integrated Control Concept enhances the precision, performance, and overall functionality of our injection molding machines. With Inovance’s cutting-edge technology seamlessly fused into our machines, we offer our clients a superior manufacturing experience, setting new standards in quality and reliability. At Guruharkrishan Machinery, modern manufacturing.

1 of 4 Fast Clamping Unit

Fast Clamping Unit

The closing side of the e-cap is designed for cycle times of < 2 seconds under continuous load. An electric drive provides the necessary dynamics. An encapsulated 5-point toggle converts these into high-precision injection moulding machine movements.

2 of 4 Reduce Energy Costs

Reduce Energy Costs

Water-cooled, all-electric drives and flywheel storage reduce energy costs by up to 50% compared to hybrid machines.

3 of 4 Dynamic Injection Unit

Dynamic Injection Unit

The injection unit is tailored to the processing of Plastics. Together with the special screws developed for this purpose, it ensures reliable processing of the melt.

4 of 4

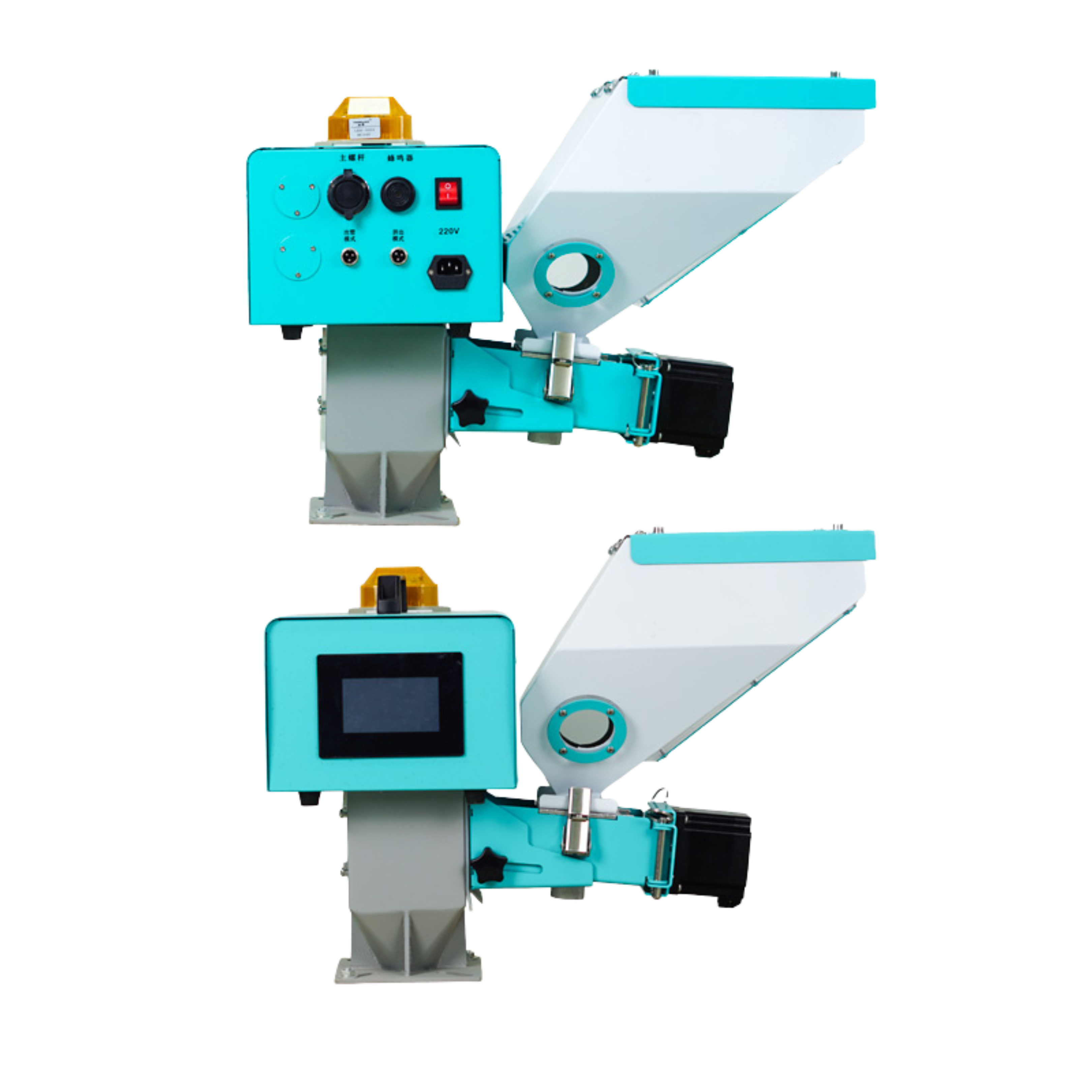

We Deals in

Auxiliary

At Guruharkrishan Machinery, our commitment to providing comprehensive solutions extends beyond injection molding machines; we also specialize in machines auxiliaries. Our range of auxiliary equipment is designed to complement and enhance the overall efficiency of your manufacturing processes.

Precision-Engineered Solutions for Advanced Injection Molding.

Our Machinery